Double braided (two in one braidline) ropes are designed from 100% high tenacity multifilament fibre. The rope is made by braiding a sheat over a braided hollow core. Double braided rope offers size for size greater strength than conventional 3- or 8-strand ropes. The central core contributes to the major part of the breaking strength. The outer sheat completes the strength and garanties the abrasion resistance of the rope. This special process of balanced twist and braiding results in a rope with superior features.

Ideal rope for use on hauling winches due to a bigger contact surface and perfect spooling on storage drums.

| Relative density | 1,14 | |

| Temperature resistance | Can be used below 0°C Melting point 218°C (Nylon 6) | |

| UV resistance | Excellent - fully stabilised | |

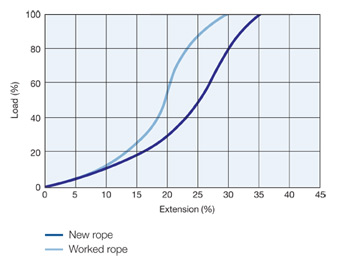

| Extension | Breaking stretch of 35% A lot of energy is stored in the rope - mind the security of people | |

| Flexibility | Soft and flexible - becomes harder in use | |

| Chemical resistance | Good resistance to alkalis - limited to acids |

| Relative density | 1,38 | |

| Temperature resistance | Flexible down to –40°C Melting point 260°C | |

| UV resistance | Excellent - fully stabilised | |

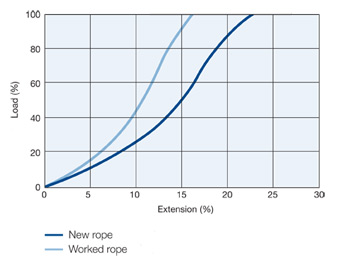

| Extension | Breaking stretch of 22% wet or dry | |

| Flexibility | Remains flexible - no water absorption | |

| Chemical resistance | Good - except to alkalis |

Length measured under reference tension according to EN ISO 9554

| Diam. Ø | Circ./ | Mass | Min. breaking load | |

|---|---|---|---|---|

| mm | inch " | kg/100m | T | kN |

| 8 | 1 | 4 | 1,52 | 14,9 |

| 10 | 1 ¼ | 6,2 | 2,36 | 23,2 |

| 12 | 1 ½ | 9 | 3,39 | 33,3 |

| 14 | 1 ¾ | 12,2 | 4,60 | 45,2 |

| 16 | 2 | 16 | 5,99 | 58,7 |

| 18 | 2 ¼ | 20,2 | 7,58 | 74,3 |

| 20 | 2 ½ | 24,8 | 9,34 | 91,6 |

| 22 | 2 ¾ | 30,1 | 11,3 | 111 |

| 24 | 3 | 35,7 | 13,5 | 132 |

| 26 | 3 ¼ | 42 | 15,8 | 155 |

| 28 | 3 ½ | 48,6 | 18,3 | 179 |

| 30 | 3 ¾ | 56 | 21,0 | 206 |

| 32 | 4 | 63,5 | 23,8 | 234 |

| 36 | 4 ½ | 80,4 | 30,1 | 295 |

| 40 | 5 | 98,8 | 36,9 | 362 |

| 44 | 5 ½ | 120 | 44,6 | 437 |

| 48 | 6 | 143 | 53,0 | 520 |

| 52 | 6 ½ | 168 | 62,0 | 608 |

| 56 | 7 | 195 | 71,7 | 704 |

| 60 | 7 ½ | 223 | 82,0 | 805 |

| 64 | 8 | 254 | 93,2 | 914 |

| 68 | 8 ½ | 271 | 101 | 995 |

| 72 | 9 | 321 | 118 | 1158 |

| 76 | 9 ½ | 361 | 134 | 1313 |

| 80 | 10 | 397 | 145 | 1420 |

| 88 | 11 | 481 | 175 | 1712 |

| 96 | 12 | 572 | 207 | 2034 |

| 104 | 13 | 667 | 241 | 2366 |

| 112 | 14 | 747 | 274 | 2688 |

| 120 | 15 | 890 | 319 | 3133 |

| 128 | 16 | 985 | 357 | 3500 |

| 144 | 18 | 1262 | 452 | 4430 |

| 168 | 21 | 1719 | 608 | 5960 |

| 192 | 24 | 2257 | 790 | 7748 |

| 216 | 27 | 2850 | 992 | 9728 |

| 240 | 30 | 3520 | 1221 | 11981 |

| Diam. Ø | Circ./ | Mass | Min. breaking load | |

|---|---|---|---|---|

| mm | inch " | kg/100m | T | kN |

| 8 | 1 | 5,1 | 1,48 | 14,5 |

| 10 | 1 ¼ | 8 | 2,27 | 22,3 |

| 12 | 1 ½ | 11,5 | 3,23 | 31,7 |

| 14 | 1 ¾ | 15,6 | 4,35 | 42,7 |

| 16 | 2 | 20,4 | 5,64 | 55,3 |

| 18 | 2 ¼ | 25,8 | 7,07 | 69,4 |

| 20 | 2 ½ | 32 | 8,66 | 85 |

| 22 | 2 ¾ | 38,6 | 10,4 | 102 |

| 24 | 3 | 46 | 12,3 | 121 |

| 26 | 3 ¼ | 54 | 14,4 | 141 |

| 28 | 3 ½ | 62,5 | 16,6 | 163 |

| 30 | 3 ¾ | 71,7 | 19,0 | 186 |

| 32 | 4 | 81,6 | 23,1 | 227 |

| 36 | 4 ½ | 103 | 28,1 | 275 |

| 40 | 5 | 128 | 34,2 | 335 |

| 44 | 5 ½ | 154 | 40,1 | 393 |

| 48 | 6 | 184 | 48,4 | 475 |

| 52 | 6 ½ | 216 | 55,5 | 544 |

| 56 | 7 | 250 | 63,5 | 623 |

| 60 | 7 ½ | 287 | 74,6 | 732 |

| 64 | 8 | 326 | 83,0 | 814 |

| 68 | 8 ½ | 375 | 95 | 936 |

| 72 | 9 | 413 | 105 | 1030 |

| 76 | 9 ½ | 467 | 119 | 1164 |

| 80 | 10 | 510 | 129 | 1267 |

| 88 | 11 | 617 | 154 | 1515 |

| 96 | 12 | 735 | 180 | 1767 |

| 104 | 13 | 862 | 208 | 2045 |

| 112 | 14 | 1000 | 240 | 2352 |

| 120 | 15 | 1150 | 275 | 2693 |

| 128 | 16 | 1310 | 310 | 3040 |

| 144 | 18 | 1650 | 388 | 3810 |

| 168 | 21 | 2250 | 523 | 5130 |

| 192 | 24 | 2940 | 681 | 6680 |

| 216 | 27 | 3730 | 854 | 8380 |

| 240 | 30 | 4600 | 1050 | 10300 |