HSCP

HSCP ropes are manufactured from extruded high tenacity copolymer monofilament fibre (melt blend of polypropylene and polyethylene + additives). This process ensures that the ropes are lightweight and fl oat. Due to an optimised production these ropes are up to 40% stronger than standard polypropylene ropes. Like 100% polypropylene ropes they absorb very little water and do not shrink. They remain flexible when wet and during use.

HSCP+

Continuous improvement in production as well in extrusion and manufacturing of HSCP yarn and rope results in a new range of ropes. HSCP + ropes offer superior features in comparison to standard HSCP ropes.

| Relative density | 0,92 (floats) | |

| Temperature resistance | Suitable for use down to –30°C and up to 100°C Melting point 170°C | |

| UV resistance | Good - fully stabilised | |

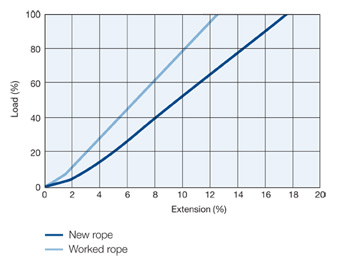

| Extension | Breaking stretch of about 18% when new - Recovery after load is good and stretch is even | |

| Flexibility | Superior handling characteristics, fibres do not absorb water and remain flexible when wet | |

| Chemical resistance | Good resistance to alkalis, acids and oil |

Length measured under reference tension according to EN ISO 9554

| Diam. Ø | Circ. | Mass | Min. breaking load | |

|---|---|---|---|---|

| mm | inch " | kg/100m | T | kN |

| 10 | - | 4,5 | 2 | 19,6 |

| 12 | - | 6,5 | 2,9 | 28,4 |

| 14 | - | 9 | 3,9 | 38,3 |

| 16 | - | 11,5 | 4,9 | 48,1 |

| 18 | - | 14,8 | 6,3 | 61,8 |

| 20 | - | 18 | 7,6 | 74,5 |

| 22 | - | 22 | 9,2 | 90,2 |

| 24 | 3 | 26 | 10,5 | 103 |

| 26 | - | 30,5 | 12,6 | 124 |

| 28 | 3 ½ | 35,5 | 14,5 | 142 |

| 30 | - | 40,5 | 16,4 | 161 |

| 32 | 4 | 46 | 18,5 | 181 |

| 34 | - | 52 | 20,8 | 204 |

| 36 | 4 ½ | 58,5 | 23,3 | 228 |

| 38 | - | 65,5 | 26,2 | 257 |

| 40 | 5 | 72 | 28 | 275 |

| 44 | 5 ½ | 88 | 34 | 333 |

| 48 | 6 | 104 | 39,5 | 387 |

| 52 | 6 ½ | 122 | 45,5 | 446 |

| 56 | 7 | 142 | 52 | 510 |

| 60 | 7 ½ | 163 | 59,5 | 583 |

| 64 | 8 | 185 | 67,6 | 662 |

| 68 | 8 ½ | 209 | 76 | 745 |

| 72 | 9 | 234 | 84,5 | 829 |

| 76 | 9 ½ | 261 | 94 | 922 |

| 80 | 10 | 290 | 104 | 1020 |

| 88 | 11 | 351 | 125 | 1226 |

| 96 | 12 | 417 | 148 | 1451 |

| 104 | 13 | 490 | 173 | 1701 |

| 112 | 14 | 570 | 201 | 1971 |

| 120 | 15 | 650 | 230 | 2256 |

| 128 | 16 | 740 | 258 | 2538 |

| 136 | 17 | 840 | 291 | 2854 |

| 144 | 18 | 940 | 321 | 3153 |

| 160 | 20 | 1152 | 390 | 3828 |

| Diam. Ø | Circ. | Mass | Min. breaking load | |

|---|---|---|---|---|

| mm | inch " | kg/100m | T | kN |

| 28 | 3 ½ | 34,5 | 14,8 | 145 |

| 32 | 4 | 44,5 | 18,3 | 180 |

| 36 | 4 ½ | 58,5 | 24,9 | 244 |

| 40 | 5 | 72 | 31,5 | 309 |

| 44 | 5 ½ | 88 | 36,8 | 361 |

| 48 | 6 | 104 | 42,2 | 414 |

| 52 | 6 ½ | 122 | 50,5 | 495 |

| 56 | 7 | 142 | 57,8 | 567 |

| 60 | 7 ½ | 163 | 65,2 | 640 |

| 64 | 8 | 185 | 73,7 | 723 |

| 68 | 8 ½ | 209 | 83,5 | 819 |

| 72 | 9 | 234 | 93 | 912 |

| 76 | 9 ½ | 261 | 105 | 1033 |

| 80 | 10 | 290 | 113 | 1111 |

| 88 | 11 | 351 | 136 | 1333 |

| 96 | 12 | 417 | 161 | 1577 |

| 104 | 13 | 490 | 182 | 1785 |

| 112 | 14 | 570 | 210 | 2060 |