Polydacron

Polydacron mooring ropes have a double construction:

The outer strand yarns are composed of copolymer yarn alternating with high tenacity polyester multifilament yarn. The inside strand yarns are made of 100% copolymer. This production process – polyester on the outside of the strand – ensures an excellent external abrasion resistance. The relative density of the rope is less than 1 – so the rope floats in water. The fibres do not absorb water and remain flexible when wet.

Rope has the same breaking strength dry and wet.

Polydacron 2nd

Continuous research efforts were leading to a new range of optimised light-weight copolymer and polyester fibre blended ropes.

| Relative density | 0,99 (floats) | |

| Temperature resistance | Suitable for use down to –30°C and up to 100°C Melting point 170°C (Polyester 260°C) | |

| UV resistance | Excellent | |

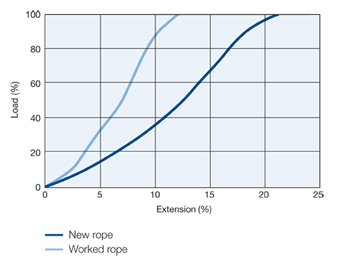

| Extension | Breaking stretch of about 21% when new - Recovery after load is good and stretch is even | |

| Flexibility | Superior handling characteristics, fibres do not absorb water and remain flexible when wet | |

| Chemical resistance | Excellent except in the presence of alkalis |

Length measured under reference tension according to EN ISO 9554

| Diam. Ø | Circ. | Mass | Min. breaking load | |

|---|---|---|---|---|

| mm | inch " | kg/100m | T | kN |

| 32 | 4 | 43,3 | 16,5 | 162 |

| 36 | 4 ½ | 52,9 | 20,8 | 204 |

| 40 | 5 | 72,2 | 30,2 | 296 |

| 44 | 5 ½ | 91,5 | 36,5 | 358 |

| 48 | 6 | 106 | 43 | 422 |

| 52 | 6 ½ | 126 | 50,5 | 495 |

| 56 | 7 | 145 | 58 | 569 |

| 60 | 7 ½ | 164 | 66 | 647 |

| 64 | 8 | 188 | 75 | 735 |

| 68 | 8 ½ | 213 | 84,5 | 829 |

| 72 | 9 | 237 | 94,5 | 927 |

| 76 | 9 ½ | 261 | 103 | 1010 |

| 80 | 10 | 295 | 116 | 1138 |

| 88 | 11 | 352 | 139 | 1363 |

| 96 | 12 | 417 | 165 | 1618 |

| 104 | 13 | 492 | 193 | 1893 |

| 112 | 14 | 573 | 224 | 2197 |

| 120 | 15 | 658 | 256 | 2510 |

| 128 | 16 | 747 | 291 | 2854 |

| 136 | 17 | 848 | 328 | 3217 |

| 144 | 18 | 946 | 367 | 3599 |

| 152 | 19 | 1057 | 408 | 4001 |

| 160 | 20 | 1171 | 451 | 4423 |

| Diam. Ø | Circ. | Mass | Min. breaking load | |

|---|---|---|---|---|

| mm | inch " | kg/100m | T | kN |

| 32 | 4 | 49 | 19,5 | 191 |

| 36 | 4 ½ | 69 | 29,5 | 289 |

| 40 | 5 | 86 | 36,7 | 360 |

| 44 | 5 ½ | 101 | 42,8 | 420 |

| 48 | 6 | 123 | 50,3 | 493 |

| 52 | 6 ½ | 137 | 58,8 | 577 |

| 56 | 7 | 159 | 68,2 | 669 |

| 60 | 7 ½ | 183 | 78,5 | 770 |

| 64 | 8 | 208 | 89,4 | 877 |

| 68 | 8 ½ | 235 | 101 | 991 |

| 72 | 9 | 270 | 113 | 1112 |

| 76 | 9 ½ | 301 | 127 | 1241 |

| 80 | 10 | 340 | 139 | 1368 |

| 88 | 11 | 415 | 163 | 1599 |

| 96 | 12 | 489 | 193 | 1892 |