Polymix

Polymix ropes are manufactured from a mixture of extruded high tenacity copolymer fibre and high tenacity polyester

fibre. The production process - applying polyester fibre to the outside of the strand yarns - ensures an excellent external abrasion resistance and internal heat-friction resistance. The combination gives exceptional resistance to cyclic loading.

The relative density of the rope is ±1,1. This means that the rope has neutral buoyancy in sea water. Fibres do not absorb water and remain flexible when wet. Rope has the same breaking strength dry and wet.

Polymix 2nd

Polymix 2nd rope range is manufactured using improved extrusion technology for the copolymer fibres in combination

with the use of new grades of polyester fibre and special rope yarn finish.

| Relative density | 1,1 | |

| Temperature resistance | High resistance to heat generated by friction Melting point 170°C (Polyester 260°C) | |

| UV resistance | Excellent | |

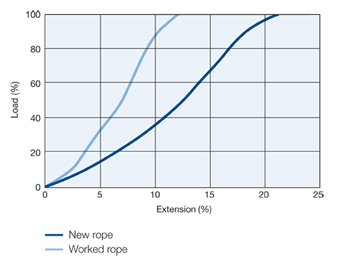

| Extension | Breaking stretch of about 21% when new - Recovery after load is good and stretch is even | |

| Flexibility | Superior handling characteristics, fibres do not absorb water and remain flexible when wet | |

| Chemical resistance | Excellent except in the presence of alkalis |

Length measured under reference tension according to EN ISO 9554

| Diam. Ø | Circ./ | Mass | Min. breaking load | |

|---|---|---|---|---|

| mm | inch " | kg/100m | T | kN |

| 32 | 4 | 68,5 | 30,6 | 300 |

| 36 | 4 ½ | 79,5 | 35,2 | 345 |

| 40 | 5 | 96,6 | 42,5 | 417 |

| 44 | 5 ½ | 112 | 49,1 | 482 |

| 48 | 6 | 128 | 55,7 | 546 |

| 52 | 6 ½ | 149 | 64,2 | 630 |

| 56 | 7 | 169 | 72,7 | 713 |

| 60 | 7 ½ | 190 | 81,1 | 795 |

| 64 | 8 | 211 | 90,3 | 886 |

| 68 | 8 ½ | 246 | 105 | 1025 |

| 72 | 9 | 267 | 113 | 1106 |

| 76 | 9 ½ | 315 | 134 | 1314 |

| 80 | 10 | 348 | 148 | 1447 |

| 88 | 11 | 415 | 175 | 1718 |

| 96 | 12 | 489 | 205 | 2013 |

| 104 | 13 | 563 | 235 | 2307 |

| 112 | 14 | 646 | 269 | 2638 |

| 120 | 15 | 725 | 301 | 2950 |

| 128 | 16 | 821 | 339 | 3328 |

| 136 | 17 | 920 | 379 | 3721 |

| 144 | 18 | 1011 | 416 | 4080 |

| 152 | 19 | 1239 | 464 | 4549 |

| 160 | 20 | 1239 | 507 | 4969 |

| Diam. Ø | Circ./ | Mass | Min. breaking load | |

|---|---|---|---|---|

| mm | inch " | kg/100m | T | kN |

| 40 | 5 | 98 | 42,5 | 417 |

| 44 | 5 ½ | 119 | 50,6 | 496 |

| 48 | 6 | 141 | 57,5 | 564 |

| 52 | 6 ½ | 166 | 68,9 | 676 |

| 56 | 7 | 192 | 80,4 | 788 |

| 60 | 7 ½ | 221 | 92 | 902 |

| 64 | 8 | 251 | 104 | 1020 |

| 68 | 8 ½ | 283 | 115 | 1130 |

| 72 | 9 | 318 | 126 | 1240 |

| 76 | 9 ½ | 354 | 144 | 1412 |

| 80 | 10 | 392 | 160 | 1569 |

| 88 | 11 | 475 | 192 | 1883 |

| 96 | 12 | 565 | 224 | 2197 |

| 104 | 13 | 663 | 267 | 2618 |

| 112 | 14 | 769 | 307 | 3011 |

| 120 | 15 | 883 | 351 | 3442 |