Koordenfabriek Van Houte Exsil

Braided or plaited

The production process consists of plaiting assemblies of untwisted yarns, single yarns, cabled yarns or strands – either around themselves or around a central core. One single assembly is called a plait. For braided or plaited ropes composed of twisted elements the twist sense of half of the plaits is “S”, the other half is “Z”.

The direction of the spiral of the braiding is opposite to the direction of the twist of the plaits. Combined construction is torque-free if the central core is also torque-free.

The most popular constructions are:

For narrow ropes:

Braided rope without core

8 or 16 plait - only narrow ropes (1-16mm diameter).

Braided rope with core

8-,16- or 24-plait around a central core; the core itself can be composed of a bundle of single yarns, cabled yarns, strands, braided or cabled ropes. In order to obtain a torque-free final construction half of the twisted core elements need to be “S”, the other half “Z” twisted. The outer braid as well as the inner core contributes to the breaking strength of the rope.

Mostly used for rope diameter from 2 to 24mm.

For thicker ropes – mooring ropes (up to 220mm):

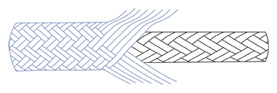

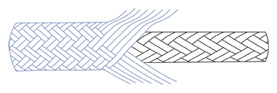

Double braided ropes (braidline - coaxial - braid on braid)

Double-braided ropes are composed of 2 concentric braided elements. Both braided parts contribute ±50% to the final breaking strength. The central core is mostly a 8- or 16-plait rope, the outer braid 24-, 32- or 48-plait.

Often used as mooring rope and for offshore applications.

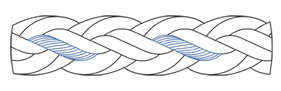

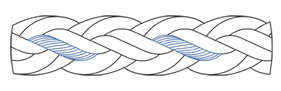

8-strand plaited rope – square line

Composed of 4 pairs of twisted strands; 2 pairs of strands “S”-twisted, 2 pairs “Z”-twisted; then plaited pair by pair.

Most popular construction for mooring ropes.

12-strand plaited rope

Same system as 8-strand but 6 pairs of strands. Rounder shape construction.

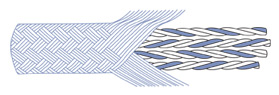

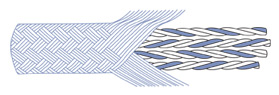

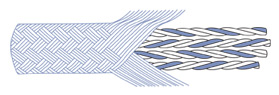

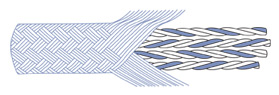

Superline

This construction is different from the above. The outer braided cover is only meant to protect and compact the load-bearing central core. The advantage is a higher breaking load for a smaller size than the above constructions. The reason for this is that there is less processing of the core. The core can be an assembly of twisted or braided ropes. The rope is utilized for heavy duty applications.

Exsil n.v. - Koordenfabriek Van Houte n.v.

Industriezone Hoogveld

Schaapveld 14

9200 Dendermonde

Belgium

T +32 (0)52 26 01 50

F +32 (0)52 37 18 98

E

info@exsil.be

webdesign by Feel Good Inc